CUSTOM MANUFACTURING

Custom Manufacturing

Let us help you reduce the cost and complexity of your manufacturing supply chain

Why Use A Custom Manufacturing Service?

- To free-up your manufacturing capacity

- Reduce costly equipment expenditures

- Lower inventory costs and improve cash flow

- Increase your manufacturing flexibility

- Tap into our technical, engineering, manufacturing, and regulatory expertise

Why Use Nachurs Alpine Solutions?

- A 75 year history of producing the highest quality chemicals

- The process flexibility of a local company combined with the resources and outreach of a global leader

- The ability to competitively source your raw materials from anywhere in the world

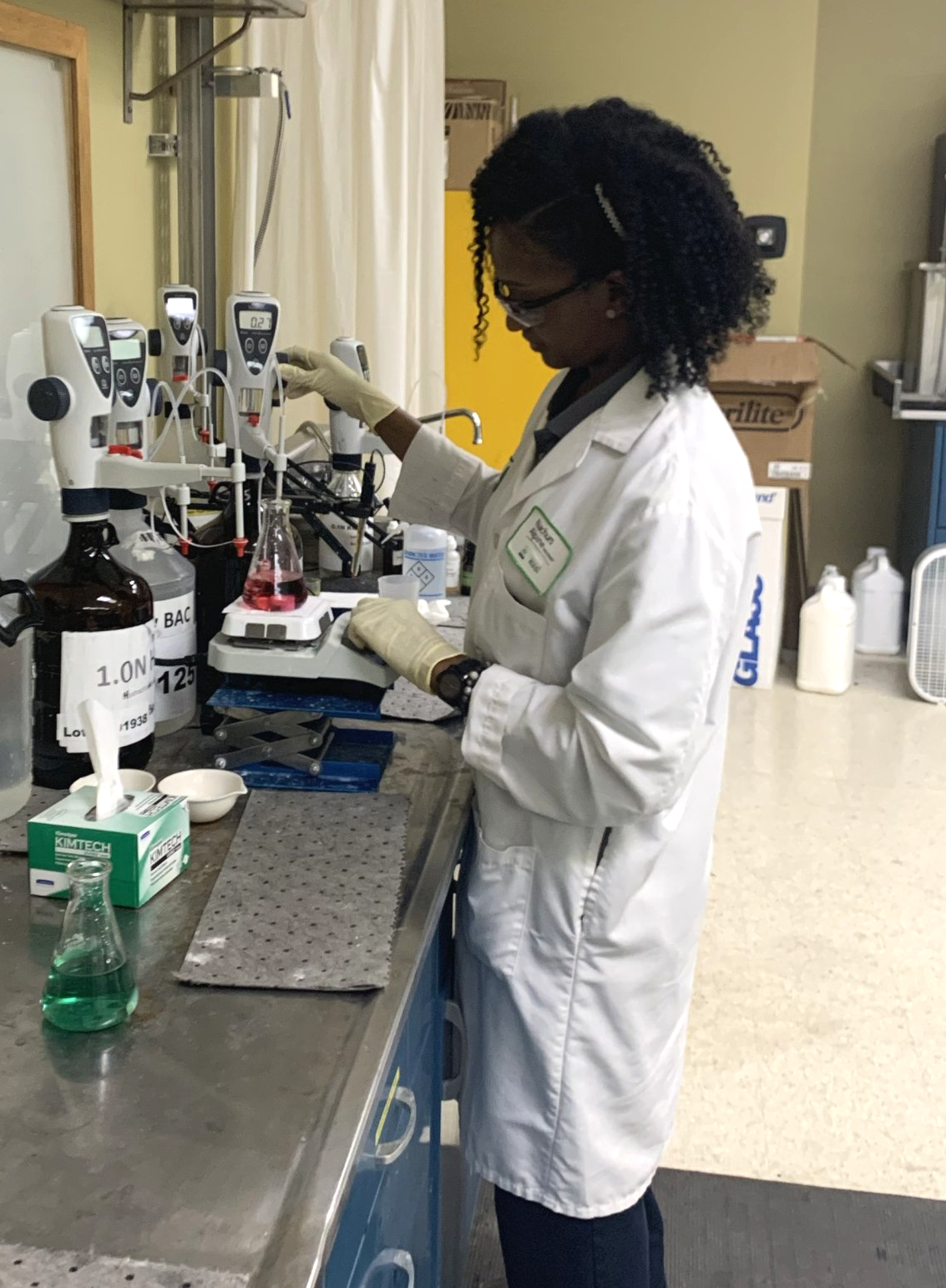

- A full-service lab to provide confidence in the quality of your finished goods

- The strongest of commitments to the security of your formulation

- The training, processes and systems to ensure complete regulatory compliance

Our Competitive Advantage Include Areas of Formulating With:

- Acetic acid

- Formic acid

- Phosphoric acid

- Potassium hydroxide

Our goal is to satisfy your customer while reducing cost and complexity for your company

Manufacturing Capabilities

- Expertise in aqueous acid-base reactions between organic carboxylic (acetic / formic) and mineral

- (nitric / sulfuric) acids with alkaline earth / organic bases (KOH, ammonia, urea)

- Acid digestions

- Aqueous dilutions and aqueous concentration

- using steam heat

- Phosphonation or Lewis type acid-base reactions

- Transesterification reactions

North American Manufacturing Facilities

- Seven sites located throughout the US and Canada, including St. Gabriel, LA which is close to many key raw materials

- Encompassing 35+ reactors, including glass and stainless steel reactors and jacketed reactors (cooling / heating)

- Processes include stripping, heat exchange, filter pressing and spray drying capabilities

Multiple Packaging & Shipping Options

- Bulk delivery available in railcar or bulk tanker

- 240+ rail cars (general purpose, ability to handle light corrosive materials, insulated & non-insulated, insulated / coiled cars, etc.)

- 40+ tank trailers with additional contract carriers at each plant

- 60+ bulk terminals across the US and Canada

- Package delivery available in totes, drums and custom package sizes

Quality Assurance - Analytical Capabilities

- Atomic Absorption

- Differential Scanning Calorimetry

- Gas Chromatography

- High Pressure Liquid Chromatography

- Liquid Physics (viscometry, etc.)

- Ion Chromatography

- Auto-titrators

- Inductively Coupled Plasma

- Others

New Paragraph

Because Quality Creates Value

©

Copyright

Nachurs Alpine Solutions